Let’s Dive In

A LITTLE INTRODUCTION TO OUR COMPANY

A young technical entrepreneur, Mr. Vijay Sethi, having vast experience of academics as well as the manufacturing sectors(Escorts-Yamaha) started SGS Engineering Works in 1996 in Govindpuri, Kalkaji in New Delhi. With high Quality Power Press tool the company was shifted to HSIIDC, Faridabad to expand & enhance the manufacturing of Sheet Metal Products.

Within a short span of time the company graduated its facilities for manufacturing the same for various industries like automobiles, electronics & electrical appliances. The organisation right from its inception paid attention to quality of its products and was successful in carving a niche in both domestic and export markets.

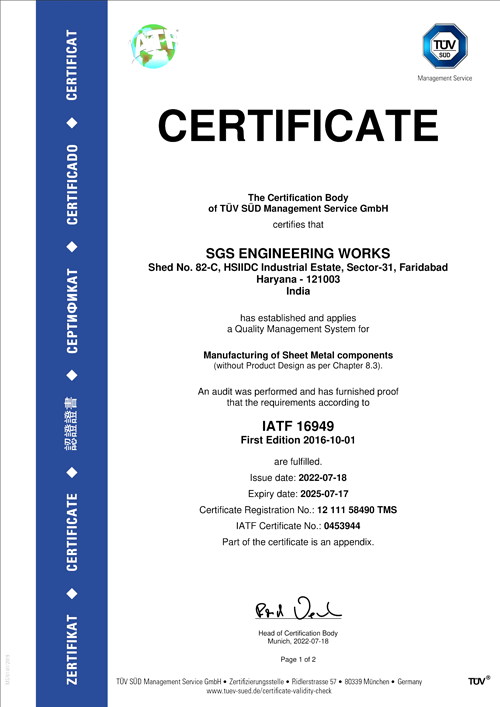

To facilitate quality at all stages, the management has established a quality management system which has been certified to IATF standards.

As of Today

Production along with Tooling of Over 350 different Sheet Metal Components

- Manufacturing of Brackets & Beams for Maruti Suzuki India Ltd.(MSIL). Green Certified by MACE, a subsidiary of MSIL.

- Spare Parts Manufacturing of Brake Assembly of both passenger & commercial vehicles.

- Inland Sale & Export of Over 50 varieties of Kit Sets for Commercial Vehicles Foundation Brakes developed at SGS.

- Manufacturing components from CRC, HRC, Spring Steel, Stainless Steel etc. with thickness ranging from 0.4mm to 5mm

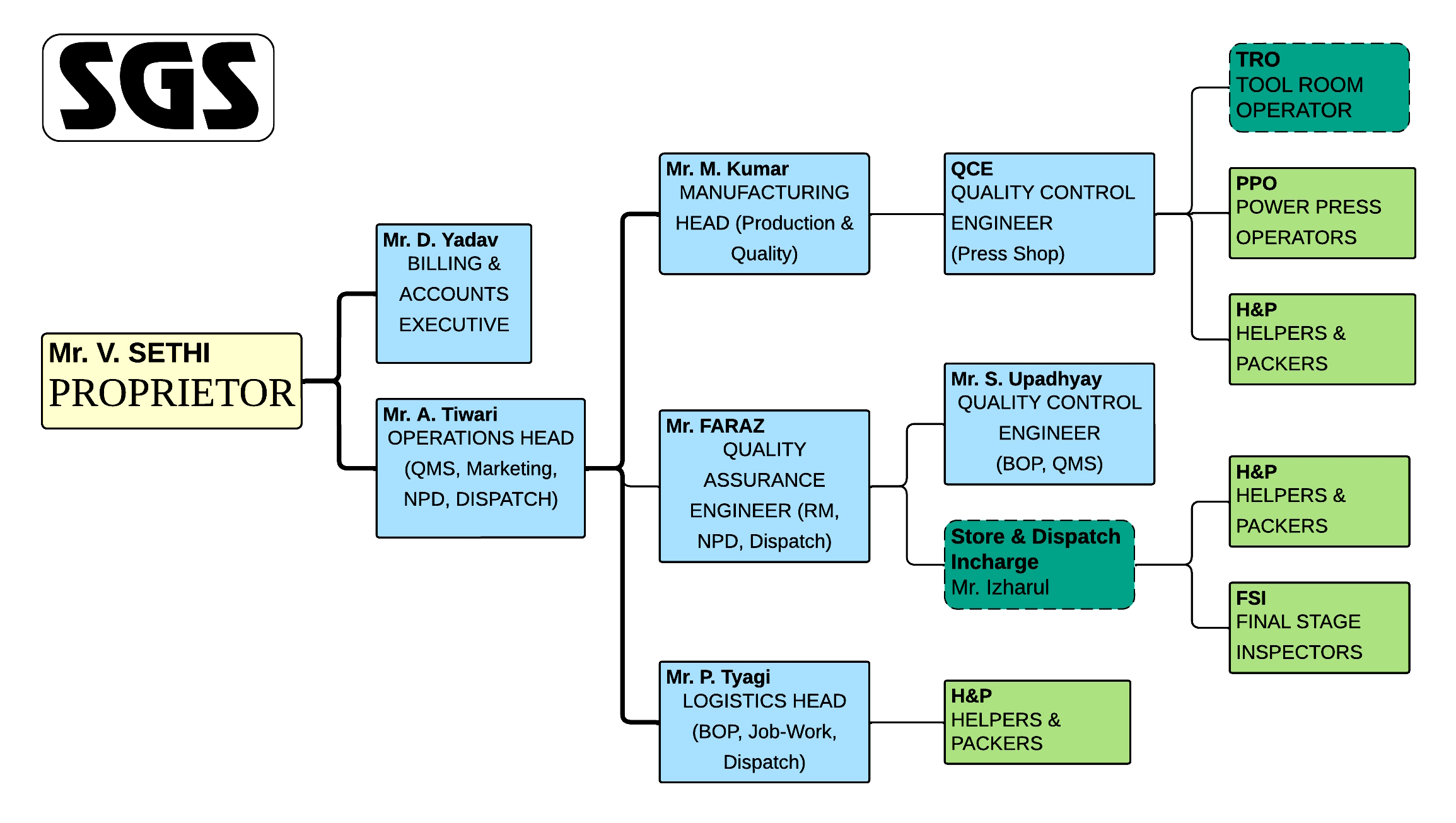

Team of over 30 Dedicated & Hardworking Associates guided by Bright Minded Team of 8 Staff Members

- IATF Certified Quality Management System(QMS) implemented by highly effective team of Staff Members.

- Trained Associates Operating at 22 Power Presses ranging from 05 to 70 Ton at two Manufacturing Sites of the Organisation.

- Associates ensuring Proper Quality of Products to Customer via thorough Final Inspection as guided by the QMS.

- Expert Staff Members & Associates performing Manufacturing, Assembly & Repair of Quality Press Tools handled at dedicated In-House Tool-Room

- Expert Out-House Support available On time, Every time for Heat Treatment, Tooling & Surface Treatment Processes as required.

Two Manufacturing Units situated in the State of Haryana, India

- The Manufacturing Sites(Shed No. 82-C & 28-B) are situated in HSIIDC Region of Sector-31, Faridabad, Haryana-121003, India.

- Along with Press Shops at Both Sites, dedicated Tool-Room available at each site with guidance from Out-Source Experts in field for prompt support & effective response.

- Out-Source processes by dedicated Suppliers with State-of-Art Machinery for Heat Treatment & Surface Treatment.

- Expert Staff ensuring Quality by means of In-House Standard Room with an array of Inspection & Testing Equipments.

Our Certificate

Our Team